UN & DOT HazMat Package Testing

Liquids, Solids, Aerosols, and Articles. APTL Identification code and +BR

Advanced Packaging Technology Laboratories is a DOT/UN recognized and certified third-party testing agency. View Certification

Advanced Packaging Technology Laboratories team of engineers and technicians are your most-trusted advisors when it comes to UN and DOT requirements. They work directly with you through the entire testing process in obtaining U.S. DOT certification for shipping packages containing dangerous goods to consulting you when it comes to intricate details and requirements of these regulations. Every step of the way they are there to guide you.

Advanced Packaging Technology Laboratories has a depth of knowledge and expertise in all nine classifications of “Dangerous Goods” containers or packages:

Class 1 – Explosives

Class 2 – Aerosols and fine explosives (gas)

Class 3 – Flammable liquids

Class 4 – Flammable solids

Class 5 – Oxidizing substances and organic peroxide

Class 6 – Toxic and poisonous materials

Class 7 – Radioactive material

Class 8 – Corrosive substances

Class 9 – Miscellaneous dangerous substances

UN/DOT HAZMAT Testing:

- 28 day stack test

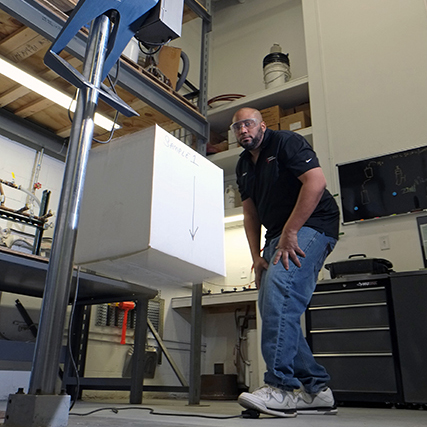

- Drop testing

- Static or dynamic compression

- Repetitive shock

- Vibration testing

- Compatibility

- Aging

- Cobb

- Package integrity testing

- Package strength testing

- Hydrostatic pressure test / internal pressure test

- IBC testing

- Vacuum leak testing

- Leakproof stress tests

Dangerous Goods and Hazardous Materials Services

- A highly responsive testing service with timely turnaround to meet your needs

- Expert assistance interpreting complicated regulatory requirements

- Certificate revalidation testing to meet new requirement of certifying bodies.

Drop Test – Can your container and contents withstand sudden shock resulting from a free fall?

Request a Quote